Liquid cleaner is one of the many thinner products that VKPAK's packaging equipment is capable of handling. Many types of facilities can use complete systems liquid cleaner fillers, cappers, labelers, and conveyors to meet their individual needs. Our machines can also fill and package a wide variety of other liquids of varying viscosity, including other industrial products and consumable liquids. Using a system of dependable machinery from VKPAK, you can increase your facility's efficiency and subsequent profitability.

VKPAK design Liquid Cleaner Filling Machine and capping machines to meet the needs of managers in various industries. Our Liquid Cleaner Filling Machine product line consists of standard and custom configurations in order to perfectly fit the specs of your application — container size, liquid type, container shape, automation implementation and integration, and more.

Brief Introduction:

Liquid Cleaner Filling Machine is one of the many thinner products that VKPAK Machinery's packaging equipment is capable of handling. Many types of facilities can use complete systems liquid cleaner fillers, cappers, labelers, and conveyors to meet their individual needs. Our machines can also fill and package a wide variety of other liquids of varying viscosity, including other industrial products and consumable liquids.

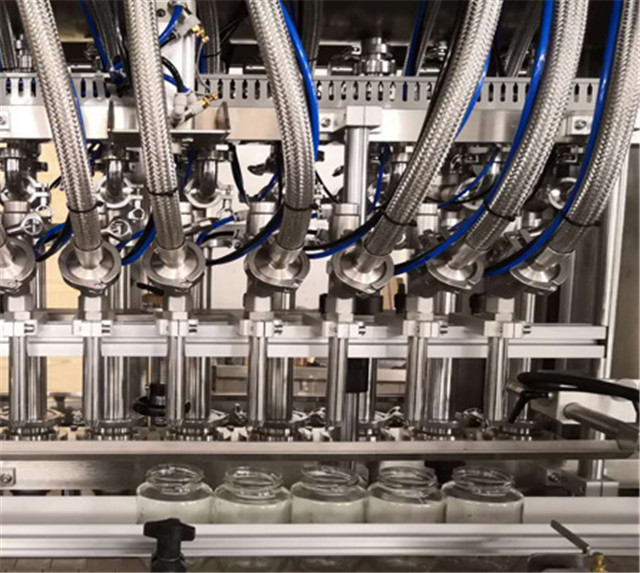

Liquid Cleaner Filling Machine is piston type filling machine which is suitable for filling both liquid and cream products.

Liquid Cleaner Filling Machine is made by in-line structure , filling head quantity can be custom-made according to different production capacity such as 6/8/10/12/16 /20 heads.

Liquid Cleaner Filling Machine is driven by servo motor which assure high filling accuracy ,also easy to set filling volume on the touch screen directly.

It is widely used in the cosmetic, foodstuff, specialty chemical, pharmaceutical, and personal care industries.

Features:

- Made by high quality 304 Stainless steel, it is durable.

- 316 stainless steel product contact parts is available for optional according to product features.

- Dosing system is driven by servo motor, it assure high filling accuracy.

- Liquid receive tray is available in case any dripping from filling nozzle.

- Diving filling head is available for optional for filling foamy liquid.

- Air blow off filling nozzle is available for sticky product to avoid tail stringing on nozzle

- Can set different filling speed on one dose.

- No bottle no fill.

- Controlled by PLC and operation through touch screen.

- No tooling needed to change over different size bottles.

- Quick-install connecting parts , it is easy to disassemble and clear machine.

Main Parameter:

| Model | Unit | VKFP | |||

| Nozzle Number | PCS | 6 | 8 | 10 | 12 |

| Filling volume | Ml | 100-1000ml/ 250-2500ml/500-5000ml | |||

| Production capacity | Bottle/h | 1000-3000 pcs/Hour ( Depends on Filling volume) | |||

| Quantitative error | % | ≤±1% | |||

| Voltage | V | 380V/220V, 50Hz/60Hz | |||

| Power | KW | 2.5 | 2.5 | 2.5 | 2.5 |

| Air Pressure | MPA | 0.6-0.8 | |||

| Air consumption | M3/min | 0.8 | 1 | 1.2 | 1.2 |