Automatic gravity liquid filling capping machine is the anti-corrosive filling made specially customized according to customer's irregular-shaped bottles with angle or bent neck. It is made wholly in anti-corrosion PP standard. It is a high-tech filling equipment which is a combination of microcomputer (PLC) controlled photoelectric sensor and pneumatic actuator.

It is specially used for high corrosive such as disinfection liquid, toilet clean fluid, and so on.With features, anti-corrosive , precise filling volume, no drip, photoelectric detection, no filling when without bottle, it is the most advanced filling machine for corrosive liquid filling in china mainland.

(1) Whole machine outside frame making material uses pp material,inner structure is made of PP material, Filling nozzles are made of strong PP and high quality Alloy. more stronger than PVC and stainless steel.

(2) Filling nozzles in 3rd version, made of PP and Alloy, more stronger and longer life, in function of “Snuffback ” and “eliminate bubbles” , no drop and no leak.

(3) There is a Overflow sensor in liquid tank, will automatically let overflow liquid into the Source, not drop in machine and ground. More clean.

This Bottle Liquid Filling Machine is gravity type filling machine which is suitable for filling thin fluid.

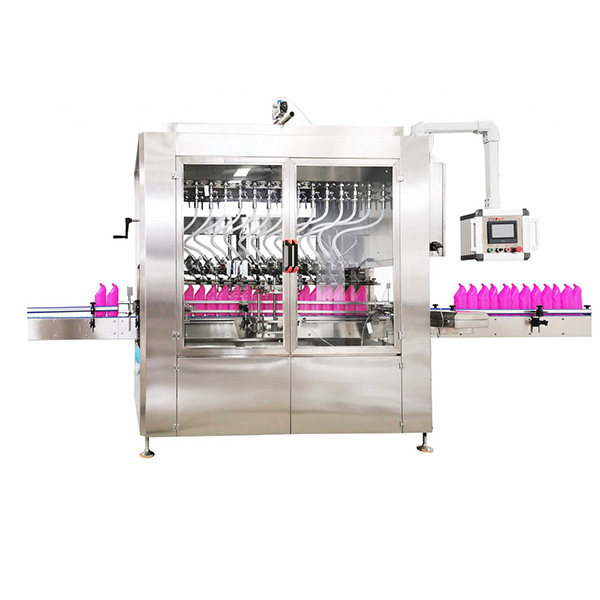

The machine is made by in-line structure , filling head quantity can be custom-made according to different production capacity such as 6/8/10/12/16 /20 heads.

Brief Introduction:

This Filling Machine is gravity type filling machine which is suitable for filling thin fluid.

The machine is made by in-line structure , filling head quantity can be custom-made according to different production capacity such as 6/8/10/12/16 /20 heads.

The filling volume is controlled by filling time, with weight feedback of each filling nozzle to PLC to assure good filling accuracy.

It is economical filling machine for filling product like glass cleaner, wine, vinegar , water, juice etc in foodstuff, cosmetic and daily chemical industries.

Features:

- Made by high quality 304 Stainless steel, it is durable.

- 316 stainless steel product contact parts is available for optional according to product features.

- Flexible machine for filling 100-5000ml

- Liquid receive tray is available in case any dripping from filling nozzle.

- Diving filling head is available for optional for filling foamy liquid.

- No bottle no fill.

- Controlled by PLC and operation through touch screen.

- Easy change over to different size bottles.

- Quick-install connecting parts , it is easy to disassemble and clear machine.

Main Parameter:

| Nozzle Number | PCS | 6 | 8 | 10 | 12 |

| Filling volume | Ml | 100-5000 | |||

| Production capacity | Bottle/h | 1000-3000pcs(Depends on filling volume) | |||

| Quantitative error | % | 100-1000ml:≤±2% , 1000-5000ml:≤±1% | |||

| Voltage | V | AC220V 380V ±10% | |||

| Consumed power | KW | 1.5 | 1.5 | 1.5 | 1.5 |

| Air pressure | MPA | 0.6-0.8Mpa | |||

| Air consumption | M3/min | 0.8 | 1 | 1.2 | 1.2 |

Characters:

*can fill both angle neck bottles and common round straight neck bottles.

*can fill corrosive liquid both without Viscosity.

* Also other models in different quantity of filling heads, YPC8/10/12/20-F2.

* Made of PP material. New design, 100% percent no liquid leaking.

* Widely used in toilet disinfection/cleaner/disinfection solution/strong acid and alkali.

*PP is much stronger than PVC and Stainless for anti-corrosive function. Also can be made in Stainless steel if buyer wants.