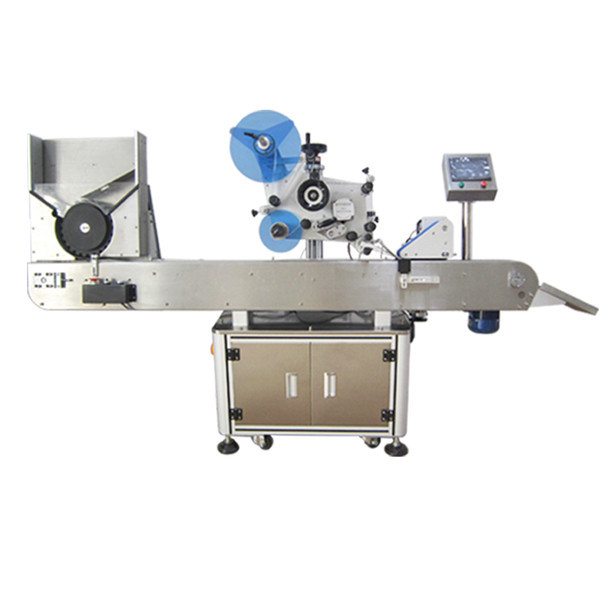

The Horizontal Wrap-Around Automatic Labeling machine has few moving parts, and adjustments are easily made. Changeovers are easy by simply swapping out the container.

The machine has been specifically designed to accommodate horizontal labeling of slim, non-freestanding cylindrical containers such as pens, test tubes, syringes and lipsticks. An angled roller conveyor ensures accurate labeling by securing the product on its side as it moves through the label head.

With decades of machinery experience, VKPAK designed this labeler through constant improvements.

Unique Horizontal Labeling Structure

Fast, stable, and precise, the horizontal wrap around automatic labeling machine ensures the most precise labeling on the container and eliminates skewing to achieve the excellent labeling efficiency.

Extremely Excellent Adaptability

The Horizontal Wrap-Around Automatic Labeling machine has few moving parts, and adjustments are easily made. Changeovers are easy by simply swapping out the container.

The machine has been specifically designed to accommodate horizontal labeling of slim, non-freestanding cylindrical containers such as pens, test tubes, syringes and lipsticks. An angled roller conveyor ensures accurate labeling by securing the product on its side as it moves through the label head.

With decades of machinery experience, VKPAK designed this labeler through constant improvements.

By using the unique auto feeder design and the slanted conveyor made from special engineering plastic roller, potential damage to fragile containers are minimized. This labeler is designed for containers that are 10-25mm in diameter, and can be equipped with an optional printer.

| Drive | Servo Motor Driver |

| Labeling Speed | 100-300PCS/Min |

| Bottle Diameter | 15mm-150mm |

| Label Length | 15mm-150mm |

| Label Height | 10mm-90mm |

| Label Exact | 1mm |

| Max Label Roll Diameter | 300mm |

| Label Core Diameter | 76mm |

| Input Power | 220V Single Phase 750W |

Usage:

It is used for automatic labeling and printing different bottles in pharmacy industry such as ampoule bottle, vial bottle, oral bottle and so on.

Features:

- Use bottle dialing device to separate the bottles. It only needs to change the bottle dialing roller when bottles are changed. One machine can be used for different sizes of bottles.

- Roller chain conveyor ensures accurate and stable labeling.

- Intuitive and user friendly touch screen makes the operation easy.

- Intelligent label control and error warning functions.

- Unique bottle breaking proof technology.

- World renowned brands of electrical components ensures the stable and reliable performance.

- Optional coder or ink jet printer realize the information printing while labeling.

It adopt horizontal type transmission , horizontal type labelling , more stable, more precise and improve working efficiency

It's applied to label the self-adhesive label on various small cylinder products, as small bottle , ampoule , lipstick ,pen etc.

This machine is widely used in electrical , pharmacy, foodstuff, beverage, cosmetic and chemical etc industries.

1. Adopt High stability German LEUZE labeling system, Panasonic PLC, Panasonic Signal transmission system. operation is stable and high-speed

2. Using touch-screen control operating system, simple, practical, efficient;

3. Adapt variety shape of object in top labeling;

4. Screw adjustment to suppress body movements accurately;

5. Synchronization chain mechanism ensure labeling smooth and precise calibration;

6. Advanced technology of pneumatic coding system, print the batch number and expiry clearly.

7. Transmission-type rolling bottles, make sure the labels attached more firmly;

8. Labeling transparent label without bubble and wrinkle;