This machine is suitable for the round-shaped products, which can be labeled with one label ,two labels, the whole circle labeling and positioning labeling. The labeling accuracy is very high and labeling speed can be reached to 1-60 pieces per minute.

It can be used separately and also can be used together with production line. Additionally, it can be printed data on the label. Now it has been widely applied in food / beverage / daily chemical products.

Application:

*For all kinds of cylindrical, tapered objects labeling, such as xylitol, cosmetics bottles, wine bottles..

*Can do One Label Wrapping Around Labeling, Two Labels in Front and Back Side Labeling, and Orientation Labeling.

*Widely used in food, cosmetic, chemical, pharmaceutical and other industries.It can work alone or connect to production line.

*Date printer can be added to print production date,batch lot and expiry date while labeling.

*Support customization.

| Labeling Precision | ±1mm (excluding product and label error); |

| Power Supply | AC220V 50/60Hz 700W |

| Conveyor Speed | 5~25 meters/minute; |

| Labeling Speed | 10~35pcs/min (Related to product, label size); |

| Sticker Out-Come Speed | Stepping Motor: 5~19 meters/minute |

| Servo Motor: 5~25 meters/minute | |

| Application Bottle Size | External diameter: Φ25-100mm; |

| Height: 25mm~300mm; | |

| Applicable label size | Label Length: 20mm~290mm; |

| Label Width(body paper width): 20mm~120mm; 180mm (option) | |

| Inner dia. of paper roll | Φ76mm |

| External dia. of paper roll | Max. Φ300mm |

| Size (L*W*H) | 2000mm×1150mm×1500mm |

| Weight | 185kgs |

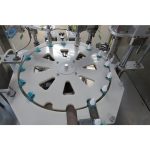

Fully automatic positioning type vertical round bottle labeling machine is a round bottle labeling machine equipment, dedicated to round bottle labeling, single label and double label can be applied, the distance between front and back double labels can be adjusted flexibly; conical bottle labeling Labeling function is available; optional circumferential positioning detection device can realize labeling at the specified position on the circumferential surface.

The equipment can be used as a stand-alone machine, or it can be used with a packaging line or a filling line

The adjustment is simple, with front and back, left and right, up and down directions, plane inclination angle, and vertical plane inclination angle adjustment seats, no dead angles for switching between different bottle shapes, simple and quick adjustment;

Automatic bottle separation, using a star wheel bottle separation mechanism, effectively eliminating bottle separation caused by bottle error, and improving stability;

Touch screen control, human-computer interaction interface with operation teaching function, parameter modification is intuitive and clear, and various functions are easy to switch;

Intelligent control, automatic photoelectric tracking, with no objects and no labeling, no label automatic correction and automatic label detection functions, to avoid wasting labels and missing labels;

Sturdy and hygienic, mainly made of stainless steel and high-grade aluminum alloy, with firm quality and meeting GMP production requirements;

With automatic shutdown function, production counting function, power saving function (when there is no production within the set time, the equipment will automatically switch to the power saving standby state)